If you hold the title at your company of Warehouse Manager, Inventory specialist, or Purchasing manager, or are in charge of financial forecasting, chances you are involved with your company’s Supply Chain.

Distribution companies can either be an overnight success or be another bankruptcy statistic if they don’t take all aspects of their supply chain seriously. All it takes is putting the right team in place, adding some daily procedures and some technical tools to run a lean, profitable company that can ultimately post ‘hockey-stick’ growth charts in front of its investors. For the rest of the start-ups that overlook this area, here are some telltale signs that your supply chain is not optimized or just broken.

Not enough inventory

If you are trying to fulfill orders and you are constantly having to ‘short’ customers on items that are out of stock, well, that’s a good sign that you have not kept up with any suggested forecasts or you have some supply chain issues that are possibly out of your control. COVID was very difficult to manage supply for many, but most industries have recovered back to pre-COVID levels. The bottom line is you can’t make money on products that you can’t fulfill, and If your company is a repeat offender (shorting customers often), you’ll also notice a decline in customer orders over time as they will move their business over to someone who has your missing product. This ‘ripple’ effect is known as the silent killer for companies because if you don’t pay attention to your customer’s buying habits, how much they buy, and how often, by the time you notice their sales decline, they are already long gone.

Too much inventory

Walk your warehouse, and if you’ve got layers of dust on your product pallets, you don’t have a janitorial problem; you’ve got too much inventory! On the flip side of the previous issue, having too much can hit you hard where it hurts most: your balance sheet. Not only have you likely paid for the product, but you don’t have the incoming funds to replenish the bank account for the prepaid inventory that is now home to new rodents in your warehouse. Add in extra costs for any additional warehouse rental fees and interest on money borrowed, and you are hemorrhaging financially, and your working capital is now on the picket lines. Companies usually offer deep discounts to get rid of excess products to help reverse this bad decision, but you can say goodbye to that great 30%-40% margin you planned when you decided to buy a trailer load of goods, only to end up at 5% or break even at best. Bottom line, If you are going to stick your neck out and purchase a lot of inventory, do one of the following:

- Look back a few years to determine what the forecasted sales will be for this product, add in factors that may increase or decrease the amount you order. (Ie. Did trucking/operating costs increase, which affected the product sell price negatively? Has the market demand gone down?) This is the basic methodology for purchasing forecasting tools often found in most software, including WMS (warehouse management systems) and ERP (Enterprise resource planning) systems.

- Go old school, get a commitment from your customers, and have it ‘pre-sold’ with a deposit upfront.

How to optimize?

The two examples are very basic scenarios that supply chains deal with daily, and while there are hundreds of additional factors that affect their forecasts, here are some things that companies should be doing regardless of size.

Open the floodgates of communication and get everyone involved. Yes, that means you need to pull information out of the dreaded weekly meetings. When the day is done, you need clear communication globally amongst your team, and these are the questions you need to ask:

Sales: What’s happening on the street? Ask your sales teams for feedback from customers. What are the new trends? Are there seasonal items that need to be purchased in advance? Are customers happy? What can we do better? ‘Good’ salesman always have their thumb on the pulse of the customer. Listen to them!

Buyers: Ask the buyers to get more aggressive in negotiating prices and terms for payment. Are there frequent price fluctuations? Should we look at alternate suppliers? Do buyers have real-time visibility of all stock in the warehouse? How has the supplier’s performance been? Are they meeting their commitments on quality, delivery, or price?

Warehouse: What is the ordering picking accuracy? Are there delays in getting orders out? Are customers informed when there are delays? Where are the choke points in the operations? Are there expedited order fees we’ve had to absorb from bad stock levels? What items have short dates? What items should we put on sale to ‘clean up’ old inventory? Are you completing regular cycle counts on inventory? The warehouse is the heart of your operations; if this is out of order, you are out of business.

Transportation: What are the current transportation fees? Are we routing using the most efficient methods? Are we using the wrong mode of transport? When was the last negotiation with carriers? The logistics industry is flooded with carriers, and many will do anything to get your business, so check rates and references often.

Finance: Know your balance sheet, The finance team is usually the gatekeeper of the budget, so you need to listen to them when they say, “No”.

IT: Are all systems integrated? This can lead to data silos and make it difficult to get a complete picture of the supply chain. How is the quality of the data for reports and forecasts? Have they kept up with the latest software? How many ‘bolt-on’ software are they running? If you have more than two or three, you may want to start looking for an All-In-One for long-term stability.

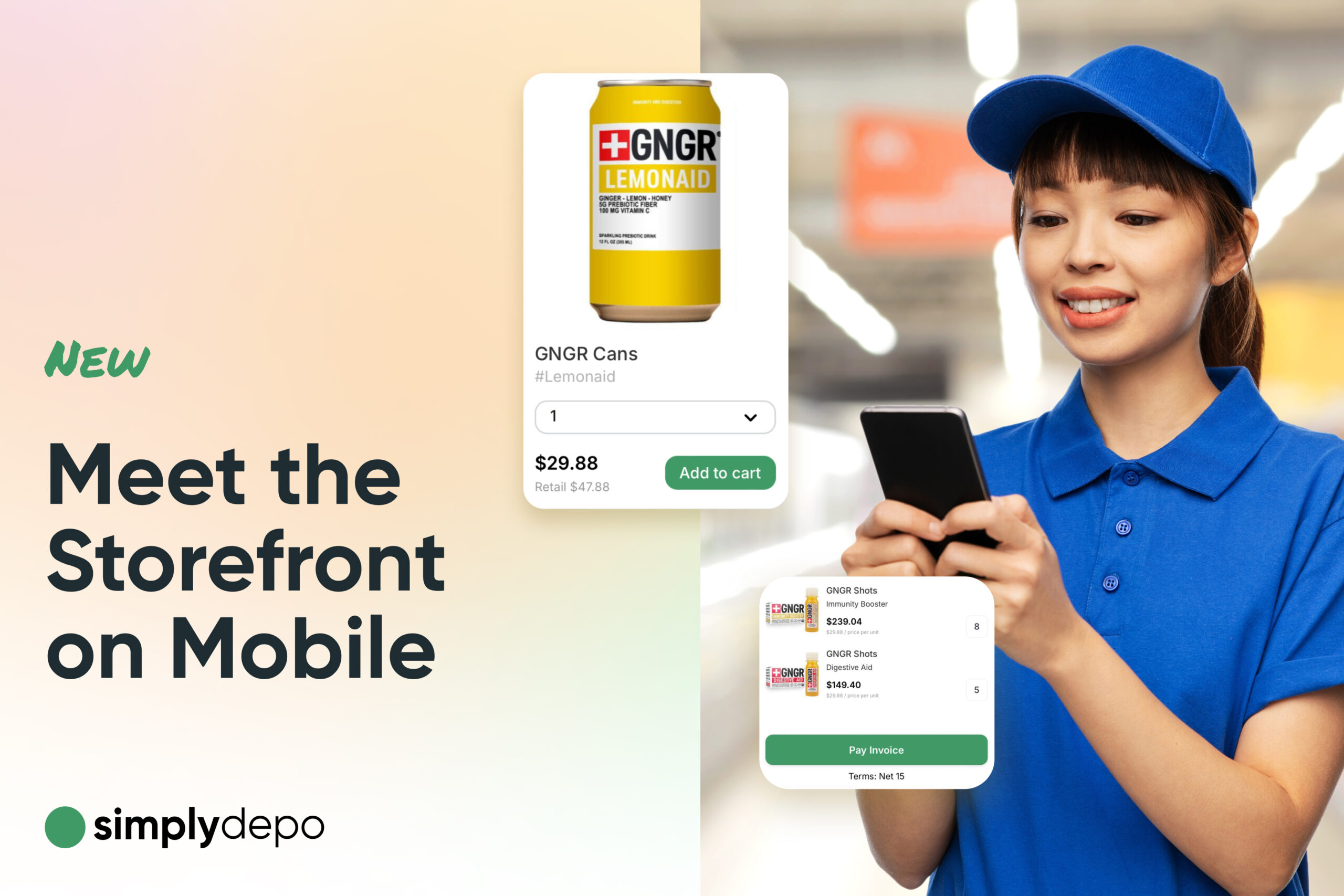

The bottom line is that companies need to collaborate and communicate effectively. If you can’t have the weekly meetings, you better make sure everyone has the technical tools to get the information they need quickly, leading to great software. You need to invest in great technology, and there are so many great software’s on the market today that it would be impossible to list them all here. The best part is that technology has become so specialized that full ERP solutions that would have cost hundreds of thousands of dollars annually can now be found in smaller, high-speed-tech-start-ups that can compete head-to-head with the market for just a few hundred dollars a month…and winning! One such software disruptor that is worth checking out is Simplydepo.com; the name says it all, and it packs all of the top tools needed to launch a CPG or distribution company, and the price is unmatched.

Must have software supply chain features are:

- Implement a supply chain management system (SCMS): Warehouse management systems (WMS) This will help you to track inventory, manage supplier relationships, and optimize transportation.

- Basic reporting tools with KPIs to help demand forecasting. This will help you to avoid stock-outs and overstock situations.

- Use automatic re-order points to trigger reminders to order when inventory gets low

- Track purchasing histories

- Task automation

- Communication: Ensure all departments can work together and get the data they need fast! Break down the silos!

- Vendor communication portals

- Integrated field sales

- B2B ordering portal, both mobile and CPU platforms

- AI integration

Do you need to focus on AI? It has already proven its worthiness, and as a matter of fact, it has been recognized as the main reason why the world’s largest distributor (Amazon) is as large and fast as it is today. Without it, they would not have been able to run the complex calculations necessary to forecast and program the most efficient operations that they are known for today. You don’t need AI to get your operations going, but you’ll want to start learning about it when you are ready to scale.

What is to gain from this?

Most companies realize bottom-line savings in the supply chain with basic data analytics when they first switch to technology-based operations. With better visuals to their data, a true cost of operation finally becomes realized, and operations are adjusted to achieve efficiencies. Double down on all the cool sale tools your team can use with the technology, and get ready to see that ‘hockey stick’ growth.

By taking these steps, you can ensure that your supply chain process is optimized and that your company can compete effectively in the marketplace.

About the Author

This article is created in collaboration with Chad Wisneski, VP of Sales & Marketing, 86 Foodservice