Vendor Managed Inventory: Outsource Smarter, Not Slower — The Distributor Advantage in 2025

In today’s volatile supply chain environment, simply managing your own inventory isn’t enough. The smartest distributors in 2025 are taking a bold step forward — handing over part of the responsibility to their suppliers through Vendor Managed Inventory (VMI). But this isn’t outsourcing as you know it. With advanced tools and real-time data, VMI is becoming a key driver for speed, transparency, and profitability

Let’s unpack what that really means.

What Exactly Is Vendor Managed Inventory?

At its core, Vendor Managed Inventory (VMI) is a collaborative approach where your suppliers — not your purchasing team — take charge of monitoring and replenishing stock. But don’t let the word “outsourced” fool you. With VMI, you’re not losing control. You’re gaining clarity and efficiency.

Here’s how it works: Your systems — or your platform like SimplyDepo — share real-time inventory and sales data with your supplier. They analyze this information and automatically ship more product before you run out. You skip the order forms, the back-and-forth emails, and the costly stockouts.

And in 2025? That simplicity matters more than ever.

“Vendor Managed Inventory is no longer a nice-to-have. It’s a growth accelerator.” — Supply Chain Trends Report 2025

Why the Shift to VMI Is Accelerating in 2025

Think about the trends defining distribution right now:

- Customer demand changes by the week

- Inventory space is limited and expensive

- Hiring and training warehouse staff is a challenge

- Distributors are under pressure to do more, faster

In this environment, VMI offers something rare: the chance to stay stocked, agile, and efficient without overburdening your internal team. But not all VMI setups are built the same.

Reimagining VMI — Driven by Data and Mobility

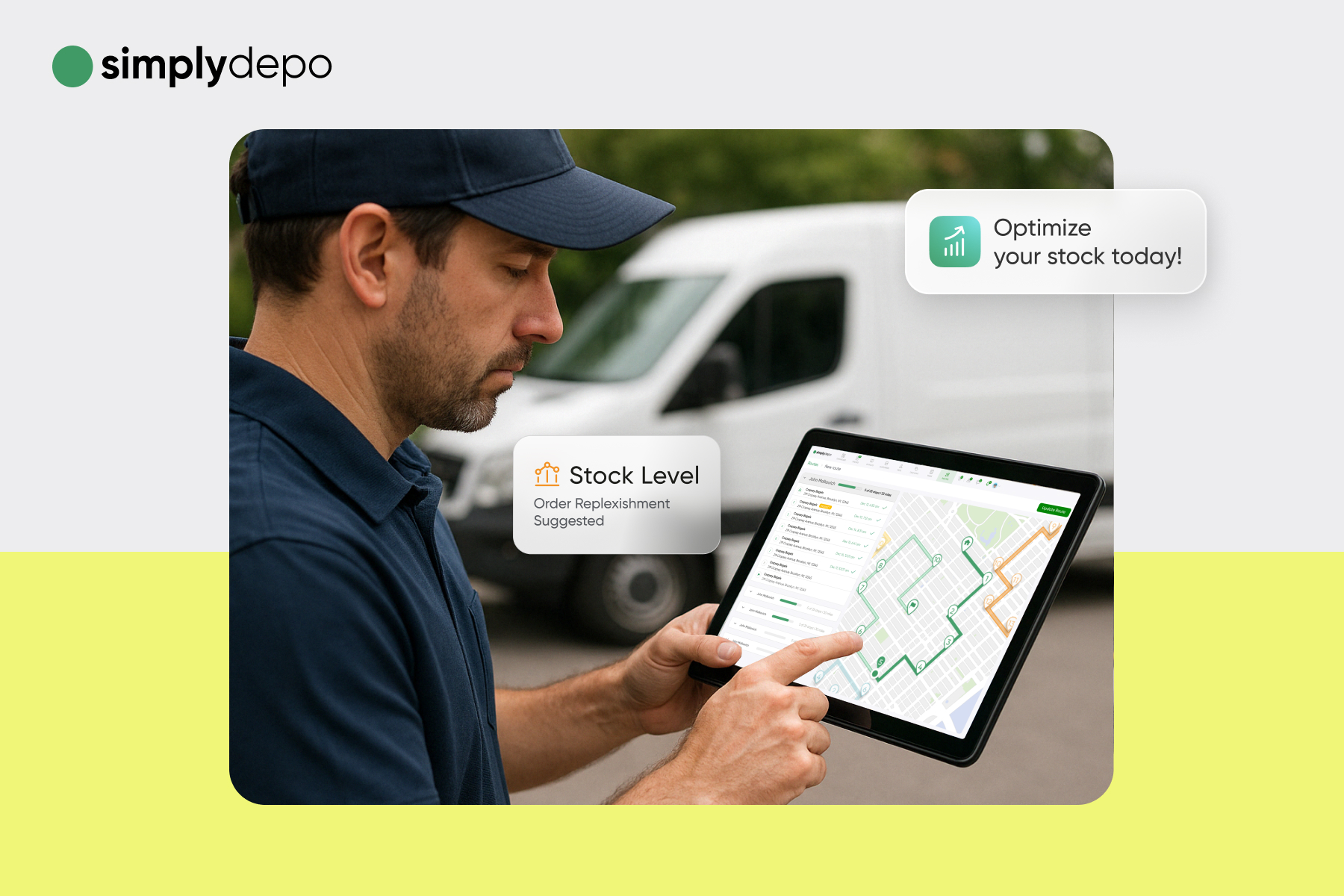

The traditional image of VMI — clunky spreadsheets, lagging ERP systems, misaligned expectations — is outdated. In 2025, successful VMI is fast, transparent, and mobile-first.

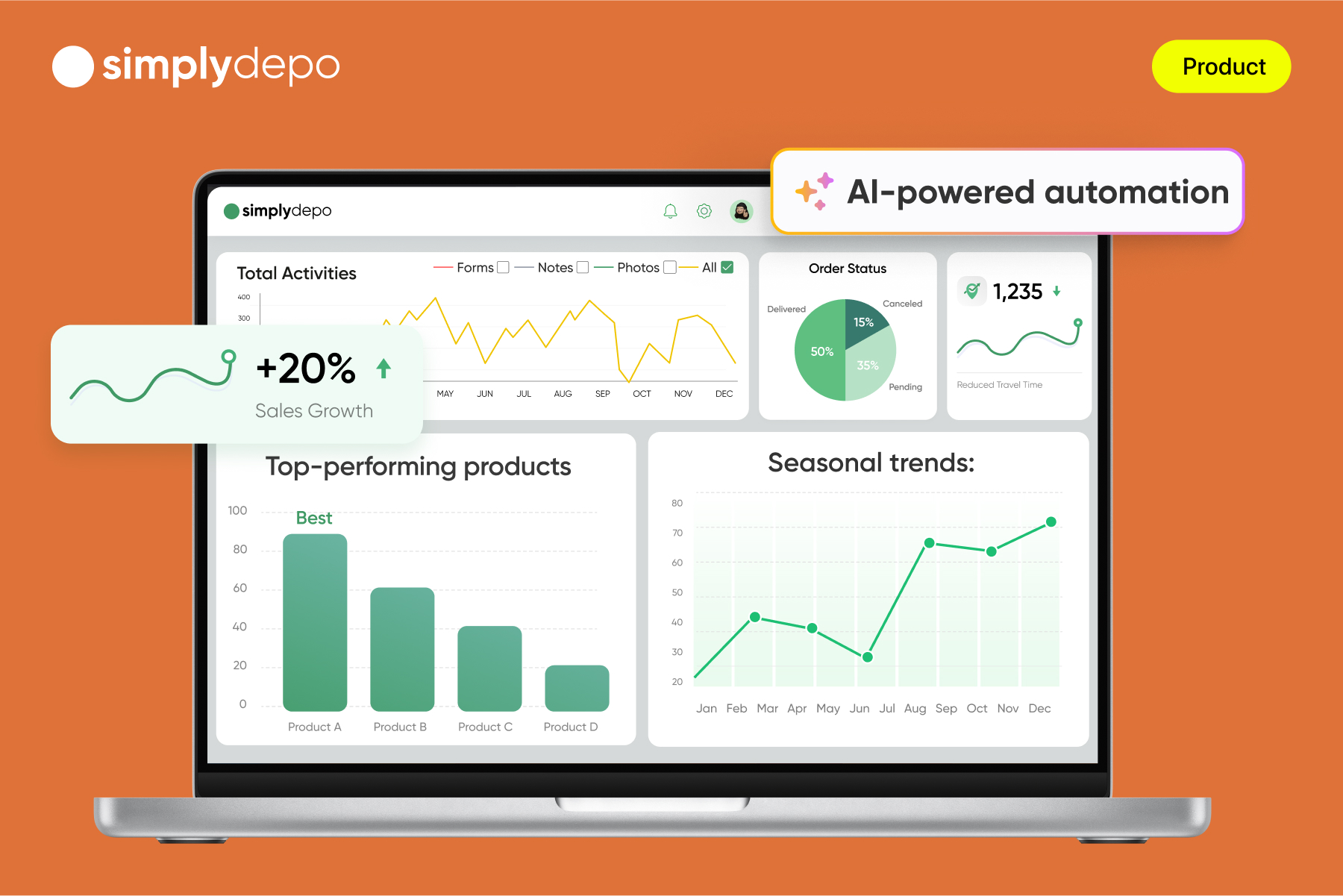

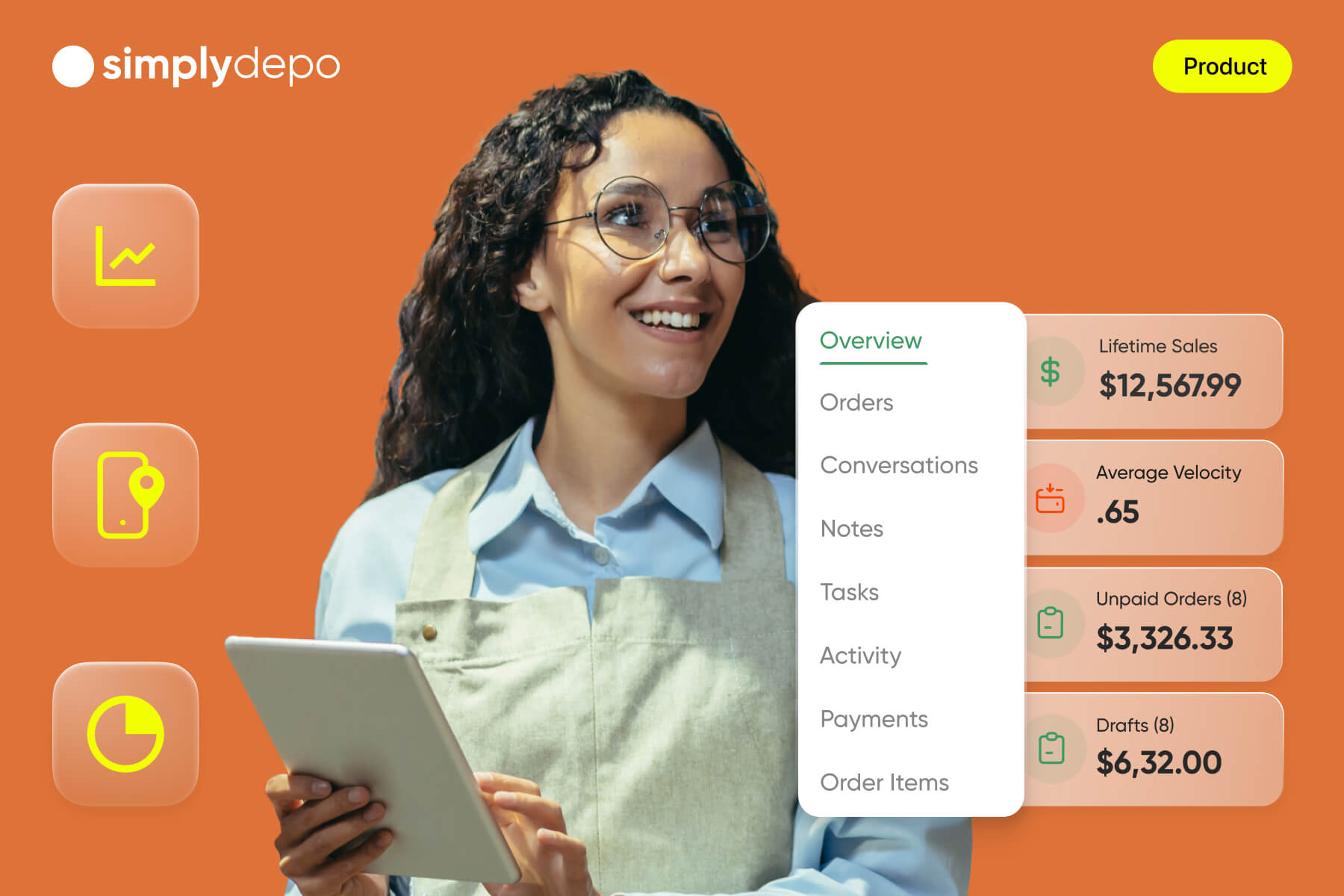

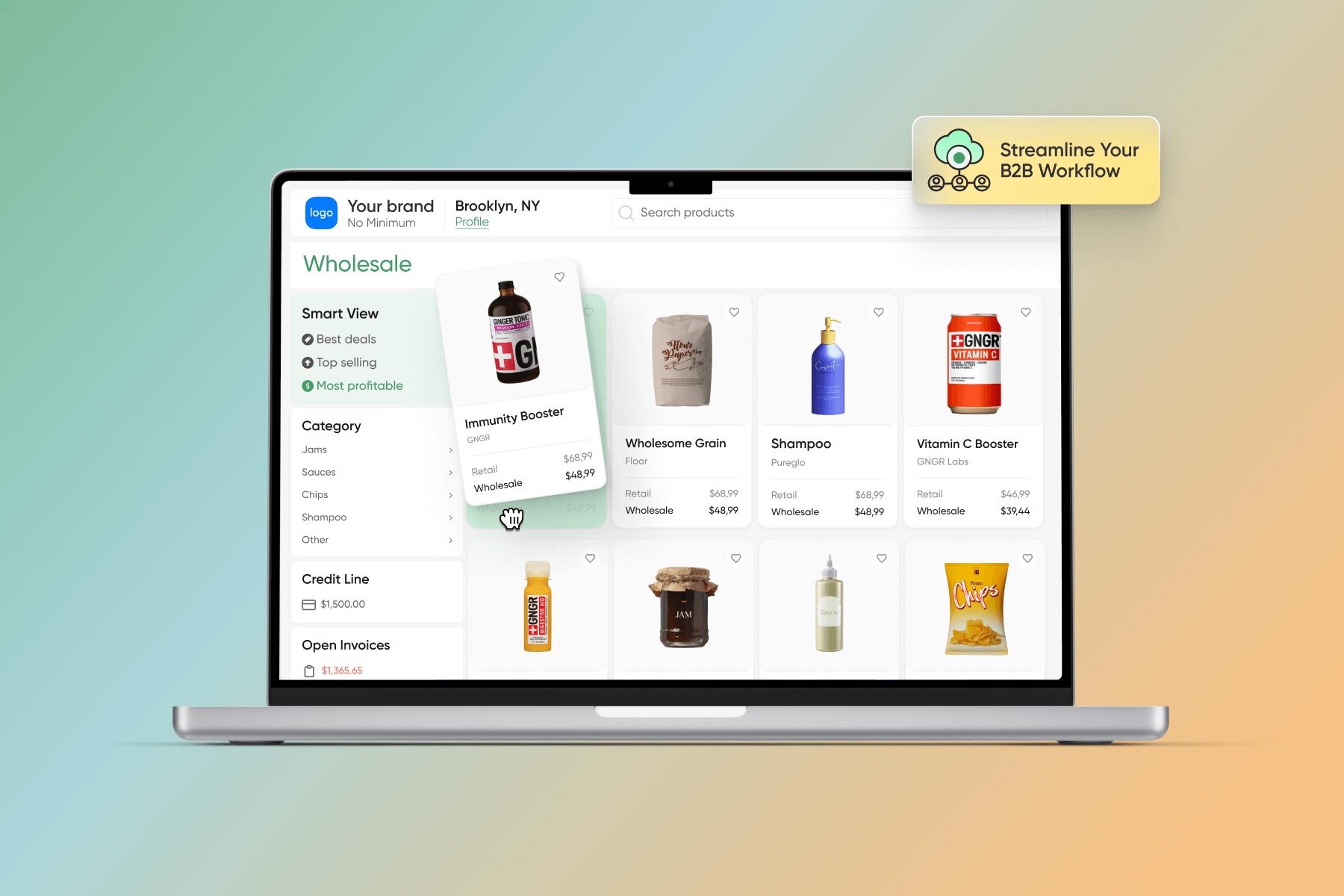

With SimplyDepo, for example, suppliers don’t have to guess your needs. They see live inventory levels, warehouse scans, sales trends — and can respond instantly. Your team? They get more time to focus on what matters: growing the business.

Let’s Talk Benefits — Why Distributors Are Saying Yes to Vendor Managed Inventory

- Fewer Stockouts, Fewer Headaches

Never get caught off-guard. Your vendor restocks you based on real data, not assumptions. - Reduced Inventory Holding Costs

Why sit on extra inventory you don’t need? VMI helps you right-size stock. - Better Supplier Relationships

VMI aligns your goals with your suppliers. You both win when the data flows. - Less Admin, More Action

No more chasing order forms. Let the system handle replenishment while your reps sell. - Visibility + Accountability

You don’t lose control — you gain a clearer picture, with performance metrics built-in.

But Isn’t It Risky? Let’s Debunk a Few Myths

“We’ll lose control.”

Actually, you’ll have better control — because your supplier sees exactly what’s happening, and you get a full audit trail.

“VMI is for big retailers only.”

Not anymore. Modern tools like SimplyDepo are built for B2B distributors and wholesalers — even small and mid-sized teams.

“Implementation will be a nightmare.”

Not if you start smart. Onboarding with SimplyDepo takes days, not months. No bloated IT project required.

SimplyDepo: Making Vendor Managed Inventory Simple, Fast, and Collaborative

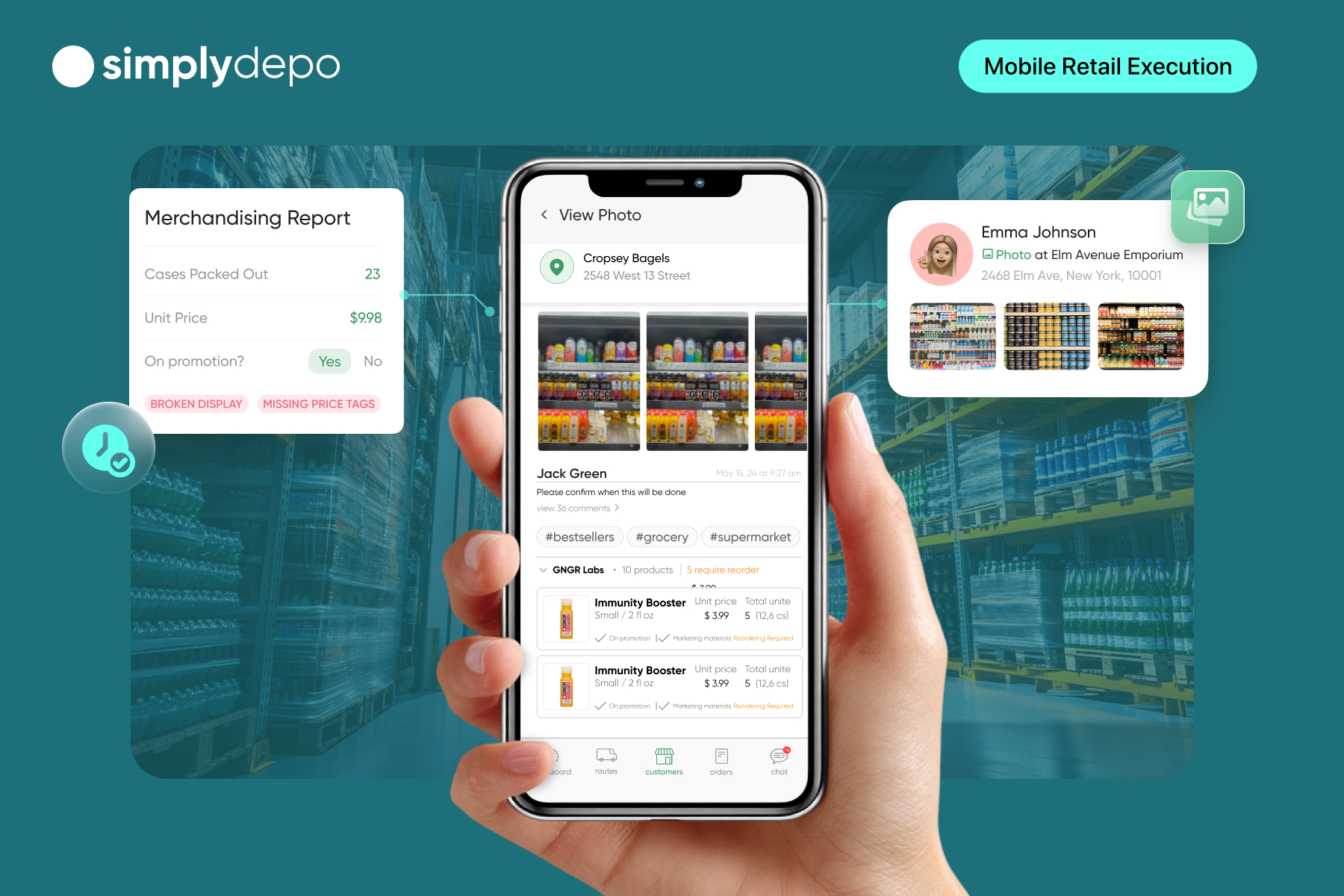

Vendor Managed Inventory works best when your tools work in real time. SimplyDepo gives your suppliers — and your team — a live feed of what’s selling, what’s low, and what’s next.

Here’s what sets SimplyDepo apart:

- Live Inventory Sharing between suppliers and your warehouse

- Barcode Scanning so restocks are accurate and fast

- Threshold Alerts that notify vendors when stock hits reorder points

- Mobile Access for reps and field staff on the go

- Shared Product Catalogs with up-to-date availability and pricing

Vendor Managed Inventory in Action: Real Distributor Use Cases

Case 1: Dairy Distributor Gets Ahead of Spoilage

A Portuguese dairy wholesaler partnered with its supplier via SimplyDepo to auto-replenish yogurt SKUs. The system triggered orders based on shelf life and sales velocity, reducing waste by 27%.

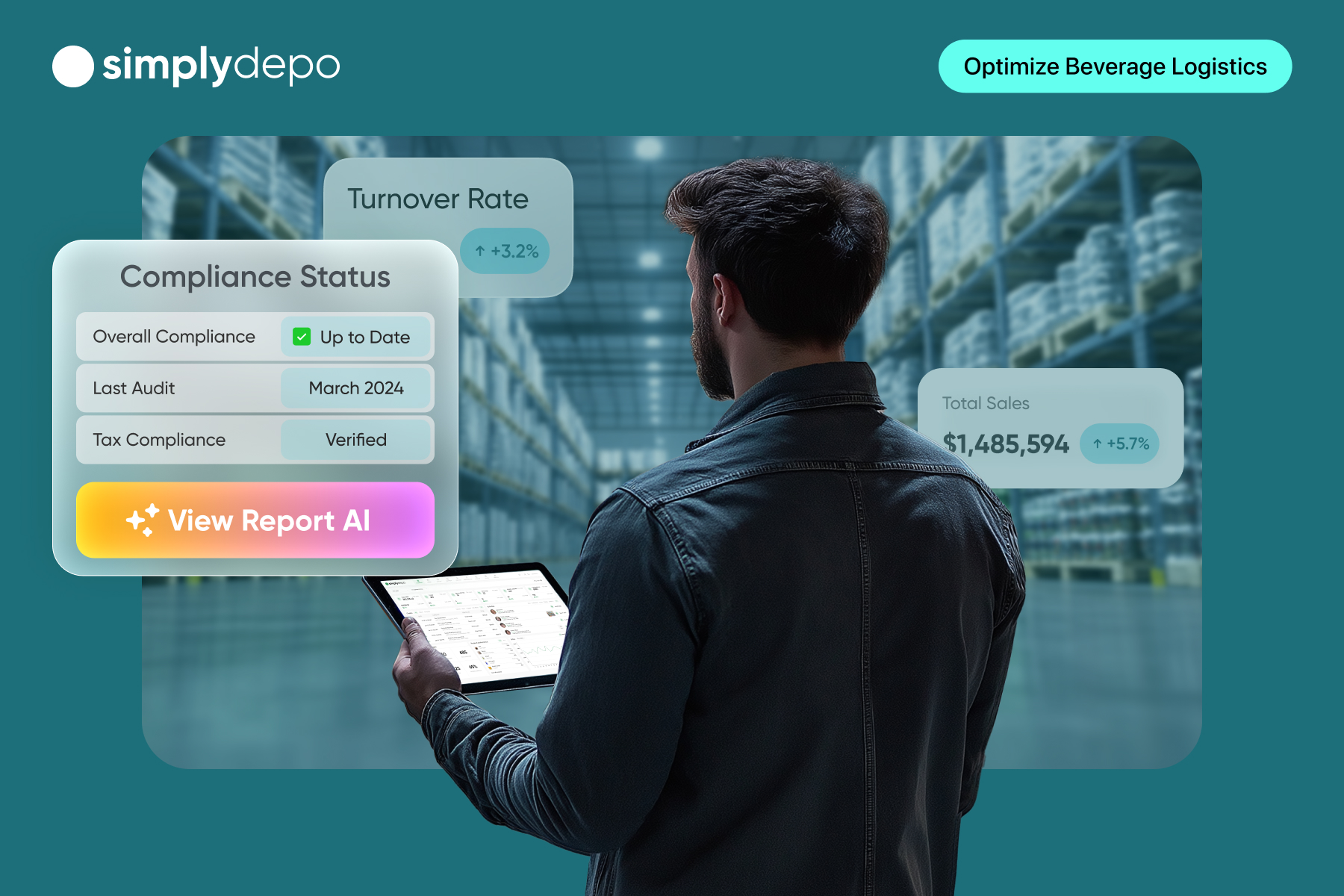

Case 2: Beverage Brand Optimizes Three Warehouses

Using SimplyDepo’s multi-warehouse view, a regional beverage brand let its suppliers manage stock regionally. It led to 22% fewer stockouts during peak summer demand.

Case 3: Field Reps Close Faster with Vendor Managed Inventory

Reps at a foodservice distributor saw live inventory before making promises to clients — increasing order accuracy and customer satisfaction.

Want to Try Vendor Managed Inventory? Start with a Pilot.

Here’s how to roll out Vendor Managed Inventory the right way:

- Choose a product category — fast-moving items work best.

- Select 1–2 suppliers who are open to collaboration.

- Define KPIs — what success looks like in 30, 60, 90 days.

- Train your internal team using SimplyDepo’s mobile-friendly tools.

- Review results together and expand what works.

You don’t need to overhaul your entire system overnight. Vendor Managed Inventory is scalable when done smart.

Why It Matters Now: The 2025 Distributor Advantage

In 2025, being reactive is too slow. Distributors who adopt Vendor Managed Inventory gain:

- Operational agility

- Lower risk of stockouts and overstocking

- Stronger vendor relationships

- More profitable workflows

You’re not giving up control. You’re gaining a competitive edge.

Ready to See Smarter Inventory in Action?

With SimplyDepo, Vendor Managed Inventory becomes a tool for growth — not complexity. Let us show you how real-time inventory sync and mobile-first tools make it easy to outsource smarter, not slower.

FAQ

What are key aspects of vendor managed inventory (VMI)?

VMI is a supply chain strategy where the supplier manages the customer’s inventory. Using real-time data, VMI optimizes stock levels and ensures timely replenishment, leading to a more efficient supply chain with fewer disruptions.

What are the types of vendor managed inventory?

- Continuous Replenishment: The supplier monitors inventory and automatically restocks based on predefined criteria, preventing stockouts.

- Consignment Inventory: The supplier owns the inventory until it’s used or sold, reducing customer costs.

Collaborative Planning: Both parties collaborate to forecast demand and optimize inventory levels for smarter, data-driven decisions.