U.S. distributors and consumer packaged goods (CPG) brands are facing faster order cycles, higher customer expectations, and smaller margins. Staying competitive now depends on real-time visibility, automation, and the ability to make decisions backed by data. That is where distribution management software changes the game.

Distribution management solutions connect every part of your operation: inventory, sales, delivery, and accounting. They replace spreadsheets and disconnected systems with one source of truth. By automating daily tasks and improving accuracy, distributors can fulfill orders faster, reduce costly errors, and give customers a smoother experience.

This guide compares the top distribution software of 2025, explains how to evaluate your options, and shows why SimplyDepo has become the go-to platform for growing distributors who want to modernize operations and increase sales.

Quick Comparison: Top Distribution Software Solutions at a Glance

Here’s an at-a-glance comparison of leading distribution software platforms, including their ideal users, standout features, pricing tiers, and demo availability.

| Platform | Best For | Key Features | Pricing Tier | Free Demo |

|---|---|---|---|---|

| SimplyDepo | SMBs, CPG & Food/Beverage Distributors | Real-time inventory, B2B ordering portal, mobile app, photo audits | Mid | ✅ Yes |

| NetSuite ERP | Large Enterprises | Finance and supply chain suite, analytics, multi-entity support | High | ❌ No |

| Acumatica Distribution Edition | Mid-Market Distributors | Cloud ERP, shipment management, flexible API | Mid–High | ✅ Yes |

| Zoho Inventory | Small Businesses | Multi-channel sync, barcode tracking, simple reporting | Mid | ✅ Yes |

| SAP Business One (Distribution) | Manufacturers & Regulated Industries | ERP with MRP, compliance tools, multi-warehouse support | High | ❌ No |

| Pepperi | Mid- to Large-Size B2B Distributors | Mobile sales app, B2B eCommerce, ERP integrations | Mid-High | ✅ Yes |

| Zoey B2B | Wholesalers & Online Sellers | Custom catalogs, quoting tools, mobile-friendly portal | Mid-High | ✅ Yes |

| Fishbowl | Small Warehouse Operations | Pick-pack-ship workflows, barcode scanning, restock automation | Mid | ✅ Yes |

💡Pro Tip: Focus on Integration, Visibility & Mobility

When evaluating distribution management software, prioritize integration flexibility, real-time visibility, and mobile accessibility. These three factors drive the highest ROI for distributors by improving accuracy, speed, and customer experience.

Pricing Overview

Pricing varies depending on your company’s size, goals, and the level of features you need. Zoho Inventory and Fishbowl offer great mid-range options for small to midsize teams that want reliable inventory control, barcode tracking, and reporting—without diving into full ERP complexity.

SimplyDepo, Acumatica, Pepperi, and Zoey B2B fit growing distributors who need automation, mobile sales tools, and retail execution features to streamline their operations and scale efficiently.

For larger organizations, NetSuite ERP and SAP Business One deliver advanced capabilities—from global financial management to compliance and deep system integrations.

Target Industries and Company Sizes

Each distribution platform is designed for a specific type of business. SimplyDepo is purpose-built for small and midsize distributors in the CPG, beverage, and food industries who want automation, inventory visibility, and retail execution tools without the complexity of enterprise ERP systems. Its intuitive interface and mobile-first design make it ideal for teams managing field sales, store visits, and direct store delivery operations.

SAP Business One often supports manufacturing and compliance-focused organizations that need advanced traceability and integrated financial management. NetSuite and Acumatica are preferred by larger distributors operating across multiple regions who require deeper analytics and multi-entity consolidation.

For distributors in the beverage sector, challenges like route accounting, temperature-controlled logistics, and regulatory compliance require specialized solutions. To help you compare your options, we prepared a detailed guide that breaks down the top technologies transforming the industry. You can explore our complete Beverage Distribution Software overview to see how automation, mobile visibility, and AI forecasting are helping beverage distributors reduce waste, improve efficiency, and scale faster. Additionally you can explore the distribution center best practices, how global companies brought success to life: Walmart’s distribution center operations, Amazon distribution centers.

Deployment: SaaS vs On-Premise

Most distributors now prefer cloud (SaaS) platforms. They are easier to maintain, scale, and update automatically. Research shows more than 80% of mid-sized businesses use at least one SaaS system for operations. On-premise setups still exist in highly regulated sectors but are becoming less common due to cost and maintenance demands.

Free Trial or Demo

SimplyDepo, Acumatica, Zoho, Pepperi, and Zoey all offer free demos or trials so you can test functionality. NetSuite and SAP usually require formal consultations before deployment.

How to Evaluate Distribution Management Software for Your Business

Selecting the right Distribution Management Software means aligning features with your workflow and growth goals. The sections below cover what to prioritize.

Core Features to Prioritize

- Real-Time Inventory Tracking – The platform should automatically sync stock levels across warehouses and channels. Accurate inventory improves order fulfillment and reduces overstocking.

- Automated Order Processing – Process automation reduces manual data entry and speeds up invoicing. Studies show automation can cut repetitive work by over 80% and reduce labor costs by up to one-third.

- Route and Territory Management – Direct store delivery (DSD) teams need route optimization, proof of delivery, and GPS check-ins.

- Predictive Analytics and Forecasting – AI-driven forecasting helps distributors predict demand and reduce waste. Businesses using predictive systems report 50% fewer stockouts and up to 65% fewer lost sales.

- Custom Dashboards and KPIs – Real-time analytics by product, rep, or region help management see what drives profit and what causes delays.

Industry-Specific Needs

Different industries require specific workflows:

- CPG and Beverage: Look for merchandising tools, promotions tracking, and retail audits. Your DMS should support retail execution similar to SimplyDepo’s field app. For guidance on scaling packaged goods distribution, read CPG Distribution.

- Food Distribution: Prioritize lot tracking, expiry control, and compliance modules.

- Wholesale and Industrial: Require bulk order handling, palletized shipping, and volume-based pricing rules.

Integrations (ERP, CRM, and Field Apps)

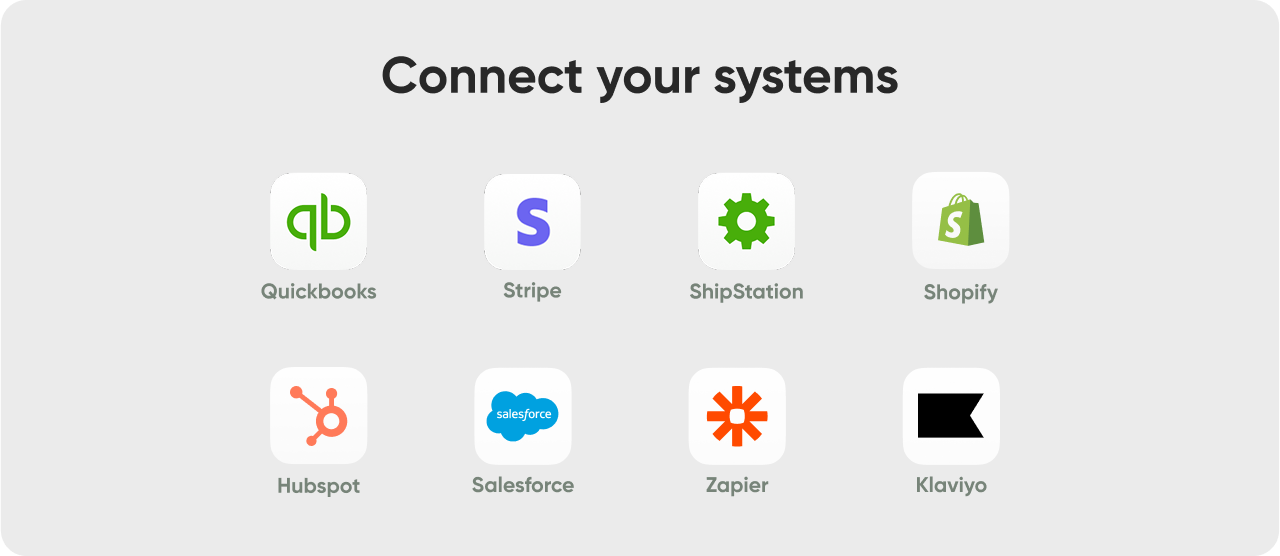

A strong distribution management software should connect seamlessly with the tools your business already depends on.

SimplyDepo integrates directly with QuickBooks, allowing invoices, payments, and credits to sync automatically between your distribution operations and accounting system. This eliminates manual entry, prevents reconciliation errors, and gives finance teams real-time visibility into sales and collections.

Beyond accounting, SimplyDepo also connects with other third-party apps to streamline your entire sales and fulfillment process.

These integrations ensure accurate data flow across departments, fewer errors, and faster reporting – so your team can focus on selling, not switching between tools.

If you are considering a full enterprise system, explore Distribution ERP Software to learn when an ERP is necessary and how it complements a DMS. For optimization, see Distribution Planning Software to understand how planning tools can improve delivery efficiency.

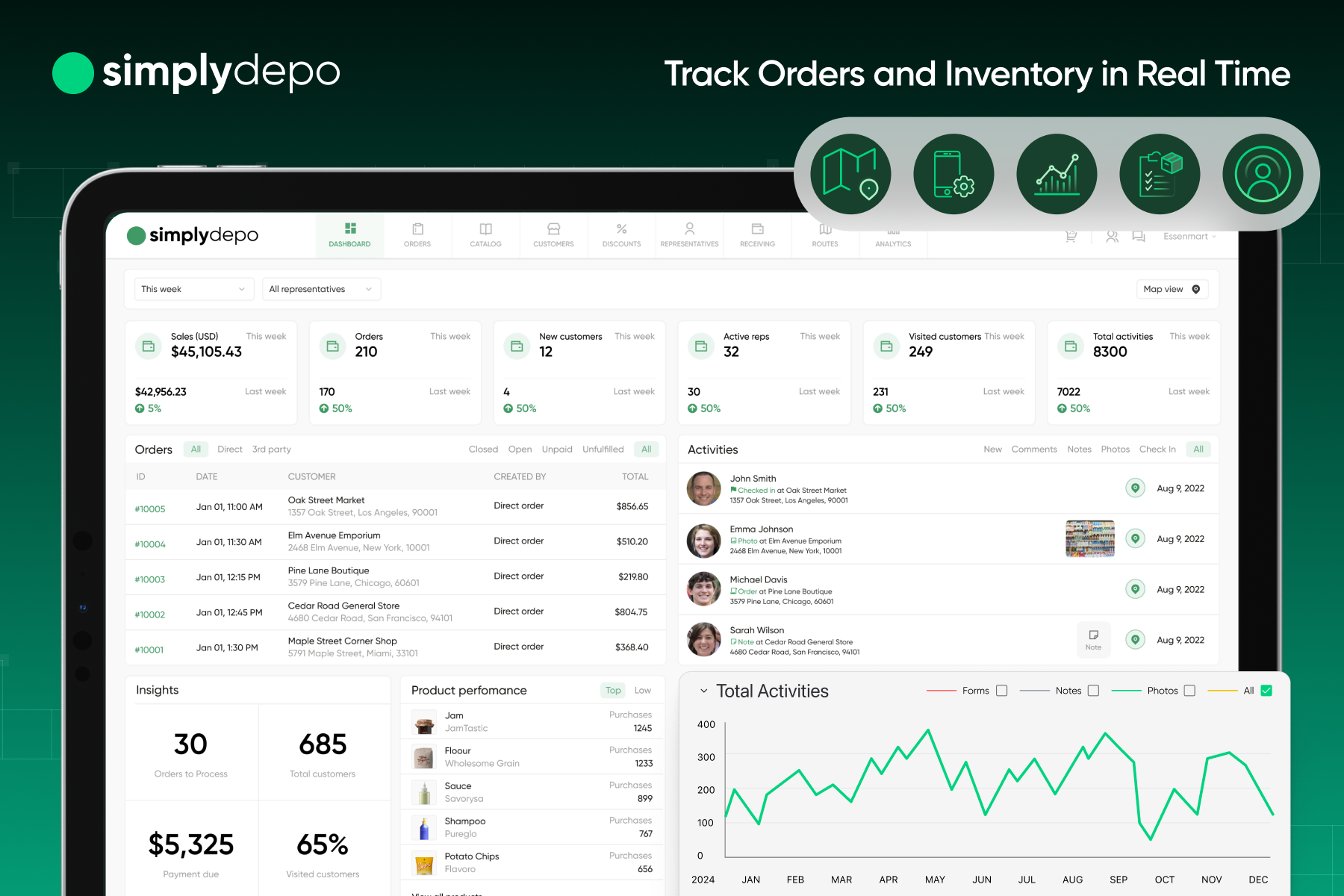

Reporting and Analytics

Distribution analytics are more than reports. They show where money leaks and where to optimize performance. AI-powered insights can reduce inventory by up to 30% and logistics costs by 20%. SimplyDepo’s analytics dashboard gives managers full visibility, helping them make faster, data-based decisions.

Mobile Access and Offline Functionality

Field reps must work anywhere, anytime. SimplyDepo’s mobile-first design lets teams place orders, check stock, and complete audits even offline. According to Deloitte, companies that adopt mobile sales tools increase productivity by more than 20%. With over 85% of U.S. adults owning smartphones, mobile accessibility is now a must.

Scalability

A future-ready distribution management software should handle new warehouses, reps, and SKUs without slowing down. Ensure that your platform scales both in features and cost structure as you grow.

💡 Pro Tip: Empower Field Reps with Mobile Tools

Equip your field sales and delivery reps with mobile-first tools that work even offline. SimplyDepo’s app keeps orders, stock checks, and photo audits running.

In-Depth Comparison: Leading Distribution Software

SimplyDepo

⭐ G2 Rating: 4.7/5 | $$

Overview

SimplyDepo is purpose-built for distributors. It combines order management, B2B e-commerce, and retail execution in one system. Unlike traditional ERPs, it focuses on field productivity and fast adoption.

Key Features

- Real-time inventory and order tracking

- B2B customer ordering portal

- Mobile field app with offline access

- Retail execution tools and photo audits

- Route accounting and proof of delivery

- QuickBooks integration

Ideal For

Small and mid-size distributors in CPG, beverage, and food.

Strengths

- Simple interface with minimal training required

- Onboarding completed within one to two weeks

- Reported order accuracy of up to 99%

- Modular design that scales as your business grows

Limitations

SimplyDepo focuses on distribution operations rather than complex global accounting. Enterprises needing full ERP financial modules may pair it with NetSuite or SAP.

NetSuite ERP Distribution Module

⭐ G2 Rating: 4.1/5 | $$$

Built for large enterprises, NetSuite offers complete financial and supply chain visibility. It integrates accounting, inventory, and analytics across subsidiaries.

Strengths: Deep automation and scalability for global operations.

Considerations: Long setup time and a complex interface that can be difficult for field reps.

Zoho Inventory

⭐ G2 Rating: 4.1/5 | $$

A lightweight, cloud-based platform for distributors. It offers barcode scanning, purchase order automation, and integrations with QuickBooks and PayPal.

Strengths: Quick setup, and ideal for small to medium size businesses.

Considerations: No field tools, limited advanced analytics and offline support.

SAP Business One

⭐ G2 Rating: 4.3/5 | $$$

An ERP with modules for production and distribution. It excels in traceability, compliance, and multi-warehouse coordination.

Best For: Manufacturers or food distributors needing strict regulation control.

Considerations: Setup is lengthy, requiring specialized training, but it delivers enterprise-grade visibility.

Acumatica Distribution Edition

⭐ G2 Rating: 4.5/5 | $$$

Cloud-based ERP for mid-market companies. It supports automated replenishment, barcode scanning, and real-time shipment tracking.

Advantages: Open API integrations, flexible deployment (cloud or on-prem), and role-based dashboards.

Considerations: Implementation often requires third-party partners.

Fishbowl

⭐ G2 Rating: 4.0/5 | $$

Warehouse management and inventory control software designed for small and midsize distributors. Supports barcode scanning, order tracking, and integration with QuickBooks.

Advantages: Affordable, easy to deploy, integrates directly with accounting tools like QuickBooks.

Considerations: Limited scalability; best suited for teams with simple warehouse workflows.

Pepperi

⭐ G2 Rating: 4.6/5 | $$

B2B eCommerce and mobile sales platform built for field reps and wholesale distributors.

Advantages: Modern B2B ordering experience with a robust mobile app for catalog presentation and on-the-spot order capture.

Considerations: Implementation and customization can take time; ideal for established B2B organizations seeking branded customer portals.

Zoey B2B

⭐ G2 Rating: 4.5/5 | $$

A B2B eCommerce and wholesale ordering platform that combines powerful backend management with an intuitive customer-facing portal. Zoey supports both sales reps and buyers with quoting tools, product catalogs, and mobile-friendly ordering.

Advantages: Branded portals, advanced pricing rules, and customer-specific catalogs make it ideal for wholesalers looking to modernize their online ordering experience.

Considerations: Limited warehouse or inventory automation compared to full ERP systems; best used when paired with accounting or inventory platforms like QuickBooks or NetSuite.

Final Verdict: Choosing the Right Distribution Platform for Long-Term Growth

Distribution is changing fast. Manual processes can no longer keep up with modern demand. Investing in a unified Distribution Management Software gives distributors the visibility and automation needed to stay competitive.

While large enterprises may benefit from full ERPs like NetSuite, small and mid-sized distributors get faster ROI and simpler operations with SimplyDepo. Its combination of mobile tools, analytics, and automation gives teams the power to work smarter and close more sales.

If you are ready to scale your distribution business, read our guide on Distribution Business for growth strategies and best practices.

Distribution management software is no longer optional; it is essential for accuracy, profitability, and customer satisfaction.

SimplyDepo delivers the balance between power and simplicity – helping distributors improve efficiency, automate workflows, and grow faster.

👉 Start your free demo today and see how SimplyDepo can transform your distribution business.

Distribution Management Software: Key Questions Answered (2025 Guide)

What is distribution management software?

Distribution management software (DMS) is a digital system that automates order processing, inventory tracking, and delivery management for distributors. It helps improve accuracy, reduce manual work, and provide real-time visibility across the entire supply chain.

What is the best distribution management software in 2025?

SimplyDepo is the best distribution management software for 2025, designed for CPG, food, and beverage distributors. It offers real-time inventory tracking, QuickBooks integration, and a mobile app with offline access—ideal for field and warehouse teams.

How is SimplyDepo different from traditional ERP systems?

Unlike complex ERP systems like NetSuite or SAP, SimplyDepo focuses on sales, inventory, and retail execution. It’s mobile-first, easy to use, and deploys in under two weeks, giving distributors faster ROI without the heavy cost or IT complexity of enterprise ERPs.

How much does distribution management software cost?

Costs vary by business size and features. Tools like Zoho Inventory and Fishbowl serve smaller teams, while SimplyDepo offers mid-tier pricing with enterprise-grade capabilities. Larger platforms like NetSuite and SAP come with higher costs and longer setup times.

Can SimplyDepo integrate with QuickBooks and other tools?

Yes. SimplyDepo integrates directly with QuickBooks to sync invoices, payments, and credits automatically. It also connects with CRM, logistics, and analytics tools, creating a unified platform that reduces errors and saves hours of manual data entry.

Does SimplyDepo work offline for field teams?

Yes. SimplyDepo’s mobile app allows reps to create orders, capture photos, and track deliveries offline. All data syncs automatically once connectivity returns, ensuring seamless operations in areas with limited internet access.

Who should use SimplyDepo?

SimplyDepo is built for small to midsize distributors in CPG, beverage, and food sectors who want automation, visibility, and field mobility without ERP complexity. It’s perfect for businesses seeking fast onboarding, mobile ordering, and integrated accounting.

Boost Sales.

Cut Manual Work.

Streamline ordering, routing, and retail execution — while giving every rep the tools to grow accounts faster.

-

+15h

Save weekly

per rep -

93%

Increase

buyer retention -

24%

Increase

in retail sales

Error: Contact form not found.