Introduction

In the world of wholesale and distribution, it’s not always the big strategies that drive profitability. Often, it’s the quiet calculations behind the scenes that make or break operational efficiency. One of the most overlooked yet powerful tools is the reorder point formula. In 2025, smart distributors are using this simple equation to slash stockouts, improve customer satisfaction, and save big on unnecessary inventory costs.

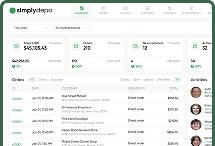

In this article, we’ll unpack how the reorder point formula works, why it’s more relevant than ever, and how distributors can automate and optimize this process with tools like SimplyDepo’s wholesale distribution software.

What Is the Reorder Point Formula?

The reorder point (ROP) is the inventory level at which you should reorder stock to avoid running out before the next shipment arrives. It considers both the time it takes to receive a new order and the buffer needed for unexpected demand.

The formula:

Reorder Point = (Average Daily Usage x Lead Time) + Safety Stock

- Average Daily Usage: How many units do you typically sell or use per day?

- Lead Time: The number of days it takes from placing an order to receiving the stock.

- Safety Stock: Extra inventory to cover variability in demand or delays.

Example: If you sell 100 units per day, your lead time is 5 days, and you keep 200 units as safety stock:

ROP = (100 x 5) + 200 = 700 units

When your inventory hits 700 units, it’s time to reorder.

Why It’s Crucial in 2025

With increasingly volatile supply chains and shifting customer demand, relying on gut instinct or outdated spreadsheets just doesn’t cut it anymore. Distributors in 2025 face:

- Longer lead times due to global shipping disruptions

- Rising inventory holding costs from inflation

- Greater pressure to meet tight delivery windows

Failing to reorder on time can lead to lost sales, strained retailer relationships, and panic buying at premium prices. On the other hand, overordering ties up working capital in dead stock.

The reorder point formula brings logic and predictability to your inventory planning, helping you balance efficiency and risk.

Breaking Down the Reorder Point Formula: Step by Step

Let’s look deeper into how each part of the formula works and how you can gather the right data.

1. Average Daily Usage

- Use 30- to 90-day sales history to calculate the average.

- Adjust for seasonality or promotions.

- Example: If you sold 3,000 units in 30 days, your average daily usage = 100 units.

2. Lead Time

- Check historical purchase orders to determine your supplier’s typical lead time.

- Factor in holidays, customs delays, or supplier inconsistencies.

- Example: Supplier usually delivers in 5 days.

3. Safety Stock

- Estimate demand variability and potential delays.

- Use a separate safety stock formula or set a buffer based on past stockout incidents.

- Example: 200 units buffer during peak months.

Add it all together to get a reliable reorder point.

Common Mistakes and How to Avoid Them

Even with a solid formula, errors happen. Watch out for:

- Static reorder points: Not updating ROPs as demand changes

- Ignoring lead time variability: Suppliers don’t always deliver on time

- Manual tracking errors: Spreadsheets get messy quickly

- Neglecting safety stock: This is especially risky during high-demand periods

How SimplyDepo Makes It Easier

Calculating reorder points manually is fine at small scale. But as your distribution network grows, automation becomes essential.

With SimplyDepo’s inventory management tools, you get:

- Real-time inventory visibility across locations

- Automated reorder triggers based on historical usage and current stock levels

- Easy-to-adjust safety stock settings

- Mobile access for sales and warehouse teams

Distributors using SimplyDepo reduce manual errors, respond faster to stock fluctuations, and avoid costly stockouts.

Explore how SimplyDepo’s full distribution management software suite can transform your inventory control.

Why Reorder Point Is a Strategic Lever

Reorder points may seem like simple math, but they have massive implications for performance. Knowing when to reorder—not just what—keeps operations smooth and customers happy.

In a high-stakes environment where every unit and everyday matters, optimizing your reorder strategy is one of the smartest moves you can make.

Ready to automate your inventory planning?

Book a demo with SimplyDepo to see how our mobile-first platform can help you track, predict, and reorder with confidence.

👉 Try SimplyDepo’s inventory tools and take control of your stock today.

FAQ

What’s the difference between reorder point and economic order quantity (EOQ)?

Reorder point indicates when to place a new order, while EOQ determines the optimal order quantity to minimize total inventory costs. Both are essential for efficient inventory management.

How can I calculate the reorder point for multiple products with varying sales rates?

To calculate the reorder point for each product, use the formula:

ROP = (Average Daily Demand × Lead Time) + Safety Stock

Apply this calculation individually for each product, adjusting the average daily demand and safety stock based on each product’s sales and variability.

What factors should I consider when setting safety stock levels?

Consider factors like demand variability, lead time variability, desired service level, and supply chain reliability. A higher service level or greater variability in demand and lead time typically necessitates higher safety stock .

Can I automate reorder point calculations using inventory management software?

Yes, many inventory management systems offer features to automate reorder point calculations by integrating real-time sales data, lead times, and safety stock parameters, streamlining inventory control processes.

Boost Sales.

Cut Manual Work.

Streamline ordering, routing, and retail execution — while giving every rep the tools to grow accounts faster.

-

+15h

Save weekly

per rep -

93%

Increase

buyer retention -

24%

Increase

in retail sales