Inventory turnover isn’t just a finance metric – it’s the heartbeat of every successful distribution business. In 2025, distributors face tighter margins, faster delivery expectations, and skyrocketing warehouse costs. The companies that manage to move inventory efficiently, restock with precision, and minimize waste? They’re growing – even in challenging markets. Those who don’t? They’re falling behind.

Understanding how often you turn over stock can help you spot inefficiencies, free up working capital, and avoid costly overstocks or stockouts. It’s a deceptively simple concept with powerful strategic value.

Why the Inventory Turnover Formula Is a Game-Changer in 2025

Let’s face it: 2025 isn’t an easy year to manage a warehouse.

- Warehouse and fulfillment costs are up

- Customers expect instant availability and zero errors

- Retailers penalize stockouts and late deliveries

In this high-pressure environment, your inventory turnover ratio becomes a performance indicator with strategic importance. High turnover signals you’re moving product quickly, minimizing storage costs, and freeing up cash. Low turnover? It can mean product stagnation, overstocking, or worse—wasted inventory.

According to Deloitte, brands with optimized turnover rates reduce carrying costs by up to 30% while improving order fill rates and customer retention.

Breaking It Down: How to Calculate Inventory Turnover

Inventory Turnover = Cost of Goods Sold (COGS) / Average Inventory

- COGS: The direct cost to produce goods sold during a period

- Average Inventory: (Beginning Inventory + Ending Inventory) / 2

Let’s put that into perspective:

If your annual COGS is $1,000,000 and your average inventory is $250,000, your inventory turnover is 4. That means you sold through and replenished your entire stock four times that year.

It’s not just math—it’s a mirror of how efficiently your business runs.

What Does a “Good” Inventory Turnover Look Like?

The right ratio depends on your category:

- 3–6 is common for general wholesale or durable goods

- 6–12+ is more typical in fast-moving goods like beverages or perishables

Too low? You’re overstocked. Too high? You might be understocked and risking sales. The sweet spot balances product availability with cash flow.

How Real Distributors Are Improving Inventory Turnover

Let’s take a look at how SimplyDepo customers are winning with better inventory control:

🍻 A regional beverage brand used SimplyDepo’s mobile order capture and barcode scanning tools to reduce delivery time by 18%. With faster order processing and real-time stock updates, they turned over inventory more frequently and reduced expired goods.

🥛 A dairy distributor implemented SimplyDepo’s smart dashboards to monitor SKU velocity. The result? A 27% reduction in spoilage, thanks to better demand forecasting and optimized replenishment cycles.

🍪 A snack wholesaler switched from monthly ordering to real-time sales-driven replenishment. With SimplyDepo’s inventory management module, they eliminated 22% of excess stock and boosted cash availability.

These aren’t just nice-to-haves—they’re mission-critical improvements in today’s distribution landscape.

5 Proven Ways to Improve Inventory Turnover in 2025

- Leverage real-time inventory data across all sales channels

- Use mobile barcode scanning to reduce errors and accelerate fulfillment

- Automate low-stock alerts to avoid missed sales opportunities

- Trim dead stock by analyzing underperforming SKUs regularly

- Enable reps with live stock access so they sell what’s actually available

SimplyDepo: Turnover-Friendly Tech for Modern Distributors

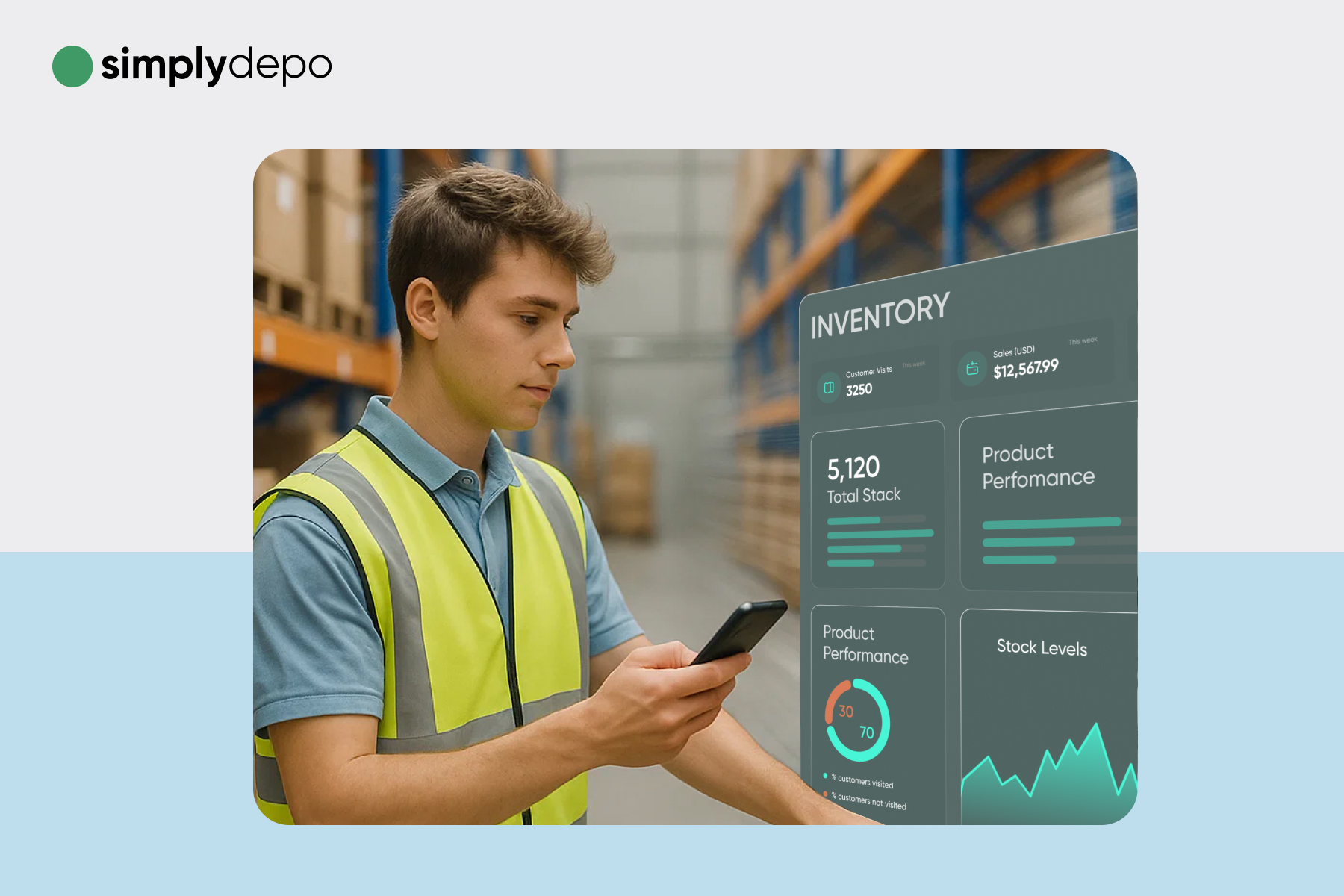

SimplyDepo is purpose-built for B2B wholesale teams that want control without complexity. It brings together inventory visibility, mobile sales, and smart automation to help you improve turnover fast:

- 📊 Real-Time Inventory Views: Know what’s available across every location

- 📱 Mobile Order Capture: Reps enter orders accurately, on the go

- 🔄 Barcode Scanning: Streamlined picking and fulfillment

- ⏰ Low-Stock Alerts & Smart Dashboards: Act before problems hit

Final Thoughts: Mastering the Metric That Drives Growth

Inventory turnover isn’t just something to track once a year—it’s a lens into how efficiently your business is running day to day. In 2025, mastering this metric helps you:

- Improve cash flow

- Reduce operational waste

- Increase order accuracy and speed

- Scale smarter, without hiring more headcount

So the real question is: Are you using the formula as a growth tool or ignoring it until it becomes a problem?

With SimplyDepo, you don’t have to guess. Get the visibility, control, and speed your business needs to compete—and grow.

FAQ

What is a good inventory turnover ratio?

A good inventory turnover ratio depends on the industry, but generally, a higher ratio indicates better performance. Typically, a ratio of 5-10 is considered healthy, meaning inventory is sold and replaced 5-10 times a year. However, this can vary depending on the type of products and business model.

How to improve inventory turnover?

- Optimize Stock Levels: Reduce overstocking and understocking by aligning inventory with demand patterns.

- Enhance Forecasting: Use data and analytics to predict demand more accurately, minimizing excess inventory.

- Streamline Supply Chain: Improve supplier relationships and delivery times to ensure quick replenishment.

- Promote High-Turnover Items: Focus on fast-moving products and offer promotions to boost sales.

- Reduce Lead Time: Shorten lead times to reduce the amount of inventory needed to meet customer demand.

Boost Sales.

Cut Manual Work.

Streamline ordering, routing, and retail execution — while giving every rep the tools to grow accounts faster.

-

+15h

Save weekly

per rep -

93%

Increase

buyer retention -

24%

Increase

in retail sales

Error: Contact form not found.