Amazon’s distribution centers are the backbone of its e-commerce success, supporting the company’s position as the largest online retailer in the world (Statista). Spread across the U.S. and around the world, these massive facilities make it possible for Amazon to deliver millions of packages each day, a scale unmatched in retail. They are more than warehouses—they’re high-tech logistics hubs designed to keep inventory flowing, speed up delivery, and create jobs in local communities.

What is an Amazon Distribution Center?

Amazon uses different types of facilities in its network, and distribution centers play a unique role. While fulfillment centers focus on picking and packing individual customer orders, distribution centers handle bulk shipments. They act as regional stockpiles, moving large quantities of goods to fulfillment hubs so inventory is always nearby when demand spikes. This setup reduces the distance packages travel, shortens delivery times, and helps Amazon keep its promises on speed and reliability.

Amazon Distribution Center Technology and Automation

Technology is at the heart of Amazon’s distribution strategy. The company introduced robotics years ago, and today its centers use hundreds of thousands of machines alongside human workers. Robots like the “Tipper” and “Echelon” unload carts, move products, and manage package flow with incredible speed. Other systems scan items from every angle, eliminating the need for manual scanning.

Artificial intelligence takes things further by predicting demand, optimizing routes, and helping robots navigate busy floors. These tools boost efficiency and accuracy while giving employees the chance to focus on higher-value tasks such as troubleshooting or quality control. The mix of robotics and human oversight has become Amazon’s signature approach to managing scale.

💡 Pro Tip

Smaller distributors don’t need Amazon’s scale to benefit from automation. Even basic tools like mobile barcode scanners or automated inventory alerts can save time and reduce errors.

Learn More

The Role of Amazon Distribution Centers in Supply Chain Efficiency

Amazon’s distribution centers are strategically placed near major markets. This positioning allows the company to move bulk shipments into fulfillment centers closer to customers, cutting shipping costs and improving speed. Instead of relying on a handful of mega-warehouses, Amazon spreads its network out, which makes it more flexible and responsive to demand changes.

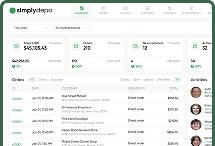

Technology plays a big role here too. Platforms like Distribution Management Software help businesses outside Amazon’s ecosystem achieve similar efficiencies. By connecting inventory, purchase orders, and delivery schedules, distributors can ensure the right products are in the right place—without overstocking or running out.

Jobs and Economic Impact of Amazon Distribution Centers

Beyond logistics, Amazon’s centers bring major economic benefits to the regions where they’re built. Each new facility employs thousands of people, from warehouse associates to engineers, and supports even more jobs indirectly through local suppliers, contractors, and services. Studies show that for every 10 direct jobs Amazon creates, roughly 9 more appear in the surrounding economy. That ripple effect makes these centers important economic engines, not just delivery hubs.

How to Ship with an Amazon Distribution Center

For businesses selling through Amazon, shipping inventory into the network requires following strict guidelines:

- Packaging and labeling: Products must be securely packed and labeled according to Amazon’s requirements.

- Approved carriers: Amazon accepts shipments only from approved carriers to ensure smooth handling.

- Booking shipments: Sellers must provide details such as purchase order numbers and shipment IDs when scheduling a delivery.

- Creating an FBA shipment plan: In Seller Central, sellers choose the items to send, prepare them in approved boxes, and create a shipment plan. The system assigns fulfillment centers, and sellers attach packing slips before dispatching goods.

💡 Pro Tip

Tools like Order Management Software can help businesses stay organized by keeping orders, shipments, and inventory in sync across multiple sales channels.

Learn More

Future Trends for Amazon Distribution Centers

Amazon continues to test new technologies to improve its operations. Robots like Vulcan, which can pick and stow items with precision, hint at more advanced automation on the horizon. Analysts predict that future facilities will become “smart warehouses,” where robots restock shelves, reorganize layouts, and adjust workflows in real time.

At the same time, Amazon is investing in sustainability by introducing electric delivery vehicles and expanding its same-day and next-day delivery services to smaller cities and towns. For other distributors, keeping up will mean adopting smarter tools to track demand and coordinate shipments. Platforms like Retail Execution Software can help companies stay competitive by improving visibility and responsiveness across the supply chain.

Conclusion

Amazon distribution centers are more than storage facilities. They are the foundation of modern e-commerce—blending automation, scale, and smart logistics to deliver goods faster and more reliably than ever before. They create jobs, support local economies, and set the standard for efficiency. For distributors and brands, Amazon’s approach is a valuable case study: by adopting modern tools and technologies, it’s possible to bring some of the same speed and precision into your own operations.

Amazon Distribution Centers FAQ

What is an Amazon distribut

Think of it as a regional stockpile. Amazon’s distribution centers hold bulk products and then feed them into smaller fulfillment centers. This setup means the items you see online are already positioned close to you, cutting down delivery time and transportation costs.

How does Amazon use automation in its distribution centers?

Amazon blends people and machines to get packages out the door quickly. Robots move shelves, unload carts, and scan packages from every angle, while employees handle exceptions and quality checks. With more than 750,000 robots at work, automation now touches most orders.

Why are Amazon distribution centers important to supply chain efficiency?

By keeping goods closer to shoppers, Amazon avoids the need to ship everything from a few mega-warehouses. Instead, inventory is staged regionally and replenished where demand is highest. This approach shortens shipping routes, lowers costs, and helps Amazon keep delivery promises.

What impact do Amazon distribution centers have on local economies?

Beyond fast delivery, these centers bring jobs and new business to communities. For every 10 people Amazon hires, roughly 9 more jobs pop up in local services like construction, transportation, or retail. Studies show they can significantly boost a region’s economic output.

How can sellers ship inventory to Amazon’s distribution network?

Sellers using Fulfillment by Amazon (FBA) need to follow set guidelines: pack items securely, label them correctly, and book shipments through Amazon-approved carriers. Once a shipping plan is created in Seller Central, products are assigned to the right fulfillment centers for processing.

What’s next for Amazon distribution centers?

The future is leaning heavily on smarter robots and sustainability. Amazon is testing robots like Vulcan that can handle delicate tasks, while also rolling out drone delivery and electric trucks. Analysts expect these “smart warehouses” to hit higher accuracy and speed than ever before.

Boost Sales.

Cut Manual Work.

Streamline ordering, routing, and retail execution — while giving every rep the tools to grow accounts faster.

-

+15h

Save weekly

per rep -

93%

Increase

buyer retention -

24%

Increase

in retail sales

Error: Contact form not found.